PurOptima Optimizes Resource Use with Hydro CIRCAL

PurOptima, renowned for its sustainable interior glass partitions and doors, has taken a significant step towards environmental responsibility by integrating Hydro CIRCAL, an innovative sustainable aluminum. Hydro CIRCAL stands out with its use of at least 75% recycled post-consumer scrap, effectively reducing the carbon footprint associated with its production. Notably, recycling aluminum consumes a mere 5% of the energy required for primary aluminum production, highlighting its eco-conscious benefits.

The move to incorporate Hydro CIRCAL in all of PurOptima’s glass and aluminum wall partitions and doors highlights the company’s commitment to low-emission practices. Hydro CIRCAL is also a significant step towards achieving a carbon-neutral status, in line with PurOptima’s commitment to circular economic principles.

Putting the ecological impact in perspective, primary aluminum produced in the U.S. carries an embodied carbon of approximately 16kgCo2, whereas Hydro CIRCAL embodies merely 2.3kgCo2. PurOptima’s transition is thus an inspiring example of how to make headway in the climate sphere— one model of progressive transformation within the architecture and design industry.

PurOptima also prioritizes efficient resource use in the processing stage, using an advanced aluminum sorting technology in which the end-of-life materials are reclaimed and cleaned while those that aren’t fit for reintroduction into circulation are discarded. The process not only minimizes energy use, but also ensures that only the finest scrap metals end up in the final Hydro CIRCAL product.

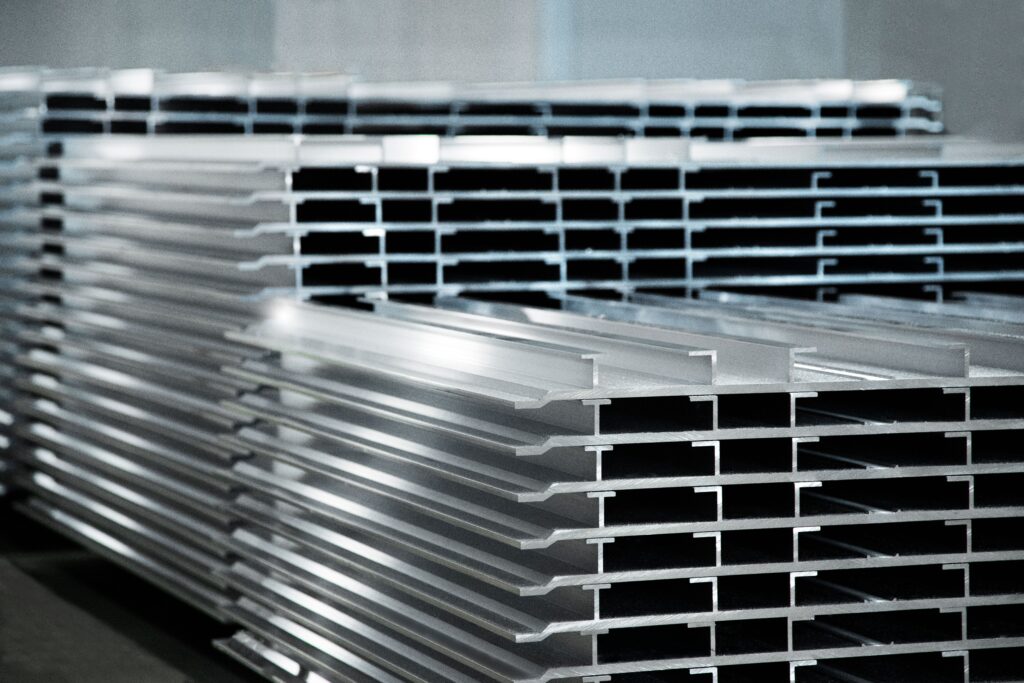

PurOptima 117 Plus wall partition made with Hydro CIRCAL aluminum

Find out more at PurOptima.

Leave a Reply