Building Biology for the Exterior

More and more I see new structures using Fiber Cement Board siding. Having lived in an OSB sided home, which was later covered in vinyl, I only assumed that Fiber Cement Board was a new discovery. The latest and greatest follow up to the failures of Louisiana Pacific's Inner Seal product, the focus of a major class action law suit, and vinyl, the non biodegradable toxin emitting wonder of the last century. It would seem we've come full circle.

Fiber Cement Board siding, exterior cladding.

After all, Fiber Cement Board is completely organic and it's concept not dissimilar from the ancient adobe process. A little straw, a little earth – add some heat, pressure and voila! You’ve got a solid natural building material. Okay, so that’s over simplifying it a bit. I’m sure something about the manufacturing processes would make Al Gore cry. However, when compared to the manufacturing process for vinyl siding, it’s grass green and not a new process at all! With origins well before the plastics boom (dating back 100 years ago purportedly to Austria), Fiber Cement Board has been around a long time, but is only now gaining popularity as Americans become more eco-conscious.

So what exactly is it? Fiber Cement Board is made of silica (finely ground sand), Portland cement and wood fibers (cellulose) broken down into individual strands, which are added to the cement mixture to provide greater strength. It is made to withstand extreme climates, insects, rot, has excellent sound absorption qualities and is fire resistant. It is so durable some manufacturers offer 30 and 50 year warranties! You can't get that with OSB.

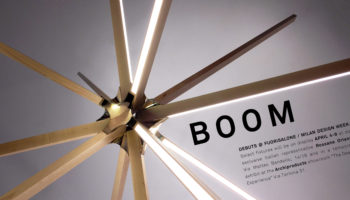

This beautiful structure I recently had the pleasure of visiting uses two different types of Fiber Cement Board. A painted lap board (seen on either side of the roll up door below) is used on the sides and rear of the home, much like that offered by James Hardie, and a heavy duty unpainted exterior cladding (in grey above) called Minerit, similar to that offered by CBF and AFCC . The lap board siding requires painting and manufacturers suggest using a 100% acrylic based paint. The unpainted Minerit used on the front of the house is a variant of the typical fiber cement process in that it is manufactured under extremely high pressure and incorporates other various minerals to make a much more dense, smooth surface that does not require paint.

For this home, architect Scott West balanced the exterior of the home visually, while also balancing the maintenance efforts of the home owner. The exotic and dense hardwood brings a needed visual warmth, but does require oiling (approximately once a year to maintain the dark rich tone) while the Fiber Cement Board is essentially maintenance free.

Cement board siding at one time, may have only sounded suitable to those of us who long for an elegantly situated concrete and steel bunker with glass accoutrements set against a heavily wooded lot, however, it is actually easily molded and can be made appealing to those with more traditional tastes if a wood grain, shingle or shake look is what you're after.

Leave a Reply