MIT Piezoelectric Acoustic Fiber

I was always good at science, but never entered the super geek category where all of junior high is spent building a supersonic rocket. That little insight into my childhood may clarify why I can explain the subject of this post—to a point. Keep that in mind before you continue reading.

A Piezoelectric Acoustic Fiber. Designed by the Fink lab at MIT’s Research Lab of Electronics.

The kings and queens of science—all who enter the glorified halls of MIT—have just published a paper in the August issue of Nature Materials that announces their new process for creating “fibers that can detect and produce sound.” More musically, the MIT geniuses describe it as “fibers that can hear and sing”—which lends them such a quality of animation that I immediately picture them with googly eyes and moustaches, busy playing microscopic guitars.

The acoustic fibers offer myriad possibilities: “Applications could include clothes that are themselves sensitive microphones, for capturing speech or monitoring bodily functions, and tiny filaments that could measure blood flow in capillaries or pressure in the brain.”

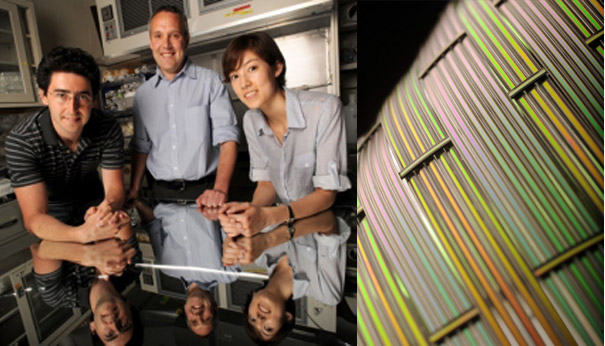

Yoel Fink, flanked by two of the graduate students in his lab who helped develop the new fibers, Sasha Stoyarov and Noémie Chocat.

Although headed by the research of Yoel Fink, the good professor also received help from his co-authors Shunji Egusa, Noémie Chocat, and Zheng Wang. Their work in Fink’s lab was supported by MIT’s Institute for Soldier Nanotechnologies, the National Science Foundation, and the U.S. Defense Department’s Defense Advanced Research Projects Agency. The fibers produced at MIT are made using a new process—and here I’ll let MIT do the talking: “Ordinary optical fibers are made from a ‘preform,’ a large cylinder of a single material that is heated up, drawn out, and then cooled. The fibers developed in Fink’s lab, by contrast, derive their functionality from the elaborate geometrical arrangement of several different materials, which must survive the heating and drawing process intact.”

The acoustic fiber is called piezoelectric, because it “changes shape when an electric field is applied to it.” Although other laboratories produce piezoelectric fibers, they do not use Fink’s method. Max Shtein, an assistant professor in the University of Michigan’s materials science department, summarizes the benefits of MIT’s fiber-making process: “Yoel has the advantage of being able to extrude kilometers of this stuff at one shot…I’m impressed by the complexity of the structures they can make. They’re incredibly virtuosic at that technique.”

The Fink lab can create acoustic piezoelectric fibers with flat surfaces, which could prove to be advantageous for certain medical and environmental uses. MIT states, “…applications of the fibers could include loose nets that monitor the flow of water in the ocean and large-area sonar imaging systems with much higher resolutions.” Most of us will have to wait to see how these fibers are implemented in new technologies, but the piezoelectric acoustic fiber is out there. I imagine it dancing to the music of the spheres while it waits for its calling in life.

All Photos: Research Laboratory of Electronics at MIT/Greg Hren Photograph

Leave a Reply