Ready? Set? Cassette!

Lights. Camera. Action! Dafna Kaplan, CEO of Cassette Systems, likens multi-family construction to making a film. While at first I found this analogy dubious—chalking it up in part to Cassette’s L.A. location—eventually I came around. After all, an innovative model requires innovative metaphors, and Cassette is truly that, proposing nothing less than a wholesale reinvention of the business of making apartments.

A Cassette Pod. Fully outfitted and on display in the company’s parking lot.

So what is Kaplan getting at with the movie metaphor? She means that the money pours forth (and too often out) during time on-site. Just as when the camera rolls, when the cranes fly across the sky, resources should be coordinated, time minimized, and performance high. In short, to make the building process efficient (and less costly), all the proverbial ducks should be in a row. But how is this accomplished with building, which is historically among the least predictable, least organized, and most costly forms of production?

Founder/CEO Dafna Kaplan and partner Nick Butcher demonstrate the stackable pod concept.

Cassette, a company that makes impeccably designed stackable one bedroom apartment pods, is betting their business that they have the answer. To return to the cameras rolling metaphor, Cassette proposes “productizing” construction—essentially doing most of the work behind the scenes, so that the actual building process is streamlined and seamless, stacking so many interlocking pods one atop the other, just like Legos.

Cassette Brings a Product-Manufacturing Mindset to the Business of Building

Kaplan’s background is a unique combination of brand strategy/PR within the automotive industry and strategic innovation for construction tech. The two trajectories coalesce in Cassette, which she characterizes as “a convergence of manufacturing and construction and its intersection with affordability.” Why, she wondered, shouldn’t recent manufacturing advancements (she specifically sites the process improvement innovations of the Japanese automotive sector during the 90s) be leveraged to improve construction? “Good design doesn’t have to be prohibitive,” she says, “remember that Target hired Michael Graves to design a teapot… one of the most famous architects in the world and you can have his teapot for 20 bucks. Cassette offers something similar—making architecture and the arrangement of space a reproducible commodity.”

Interior images of a Cassette pod. Design by Craig Hodgetts and Ming Fung.

Here, we drill down into exactly how Cassette is taking an abstract concept—the pleasing distribution of all the elements of an interior space—and making it a concrete, sell-able product.

Q: Talk about the name. Why “Cassette”?

A: For those of us who remember them, there’s a sort of satisfying analog—a mechanical sensation of popping something into place. But of course with cassette tapes it was never about the box but rather something magic inside. It’s also a beautiful word. We didn’t know this before, but I just found out that in some cities in France they use “cassette” to refer to apartments. Also, we didn’t want to go with a coinage, like they do so often in Silicon Valley, and forever get punched by spellcheck.

Loaded up and ready to be clicked into place.

Q: How is Cassette different from other modular approaches?

A: Our business is productizing the apartment, rather than offering prefabrication services for custom-designed projects. In the traditional model, you change the product every time, so you lose the opportunity to keep going with that efficiency curve. Every time you start a new project, you’re essentially reinventing the process, starting from scratch in a sense. And to make it even worse now you’re dealing with 80 different companies, missing the opportunity for everybody to improve in that process together. That’s what Cassette aims to do differently: we’re saying this is the product and we’re just going to keep making this product better. By taking the design and engineering process out of a large chunk of the development process on every project, we have the ability not only to reduce risk, speed, and cost on half of a building—we now introduce to real estate the ability to decrease costs over time by cumulatively using the same unit.

Kaplan says she “stands on the shoulders of other companies.” Examples of early innovations in modular multi-family include Kisho Kurokawa’s Nagakin Tower (above) and Moshe Safdie’s Habitat 67.

Q: As much as I love the concept and recognize the potential for increased affordability, I wonder if there’s a bit of a dystopian feel to this. People still want to feel like their home is unique, somehow reflective of their personality. Do you think the homogeneous nature of the units is in any way an impediment?

A: Think about the end user who’s moving into an apartment that they’re paying too much for in Los Angeles or San Francisco. What are their expectations? There’s not a lot of great product out there in the rental market and that’s where it’s exciting for us. We actually get to design something with the end user in mind rather than the developer throwing something together just because it might fit the financial model. This aspect of it is gratifying for us because with Cassette someone actually gets to enjoy an amazing space.

Everything in its place. Cassette’s impeccably organized kitchen/dining room.

Q: What’s unique and different about the building science of these modules? Particularly with regard to how they accrue on-site efficiencies during building/stacking?

A: In simple terms, we’ve designed an apartment product that optimizes shipping and installation without sacrificing live-ability. On a construction site, this means we don’t cut our boxes apart, we don’t weld them or require any invasive traditional forms of construction to make them connect. There is an elegant connection system that happens at the rooftop, and that stays 100% out of the units themselves during installation and site construction.

Traditional modular construction isn’t so seamless. Once set into place, units require significant assembly, connection, and exterior finishing.

Q: What is the role of the developer/builder in a Cassette project? In what ways does the Cassette model forecast a change in the traditional roles of developers and builders?

A: The developer makes the decision to purchase Cassette units, and the builder constructs the foundations, the roof system, and any elements of the building that are not the actual apartments. We provide easy-to-follow templates for how to prepare those elements to receive a Cassette unit or stack of units.

On site at a build with a Cassette collaborator.

Q: How can these units be made affordable in high-cost markets like L.A., San Francisco, or N.Y.? Is there a risk of inflation and higher price/sq. ft. with these units simply because they’re better designed and hence will experience higher demand?

A: Out of the gates, even before achieving scale as a product company, we are pleased to say that a building using Cassette apartments in those cities would already be competitive and in many cases lower-priced than a site-built version of the same building. Our aim over the next three years is to use the power of industrialization and a commitment to this product model to actually bend the construction cost curve down for the first time in memorable history.

San Francisco Skyline. Make room for Cassette! Photo by Jared Erondu on Unsplash.

Q: Is there only one Cassette module in terms of size, layout, and finishes? Will there be customizable options and perhaps different-sized units?

A: Today we have one unit type, with an option to use our window system or sliding door system (in case the developer wants to attach balconies).Our commitment is to sell that, deliver it well every time, and to bring its cost down over time, AND to make our product better and better every year, just like a car company would commit to a model for a decade and minimally change that model over time. If we are fortunate enough to win the hearts and minds of the development community, we will see about a second product.

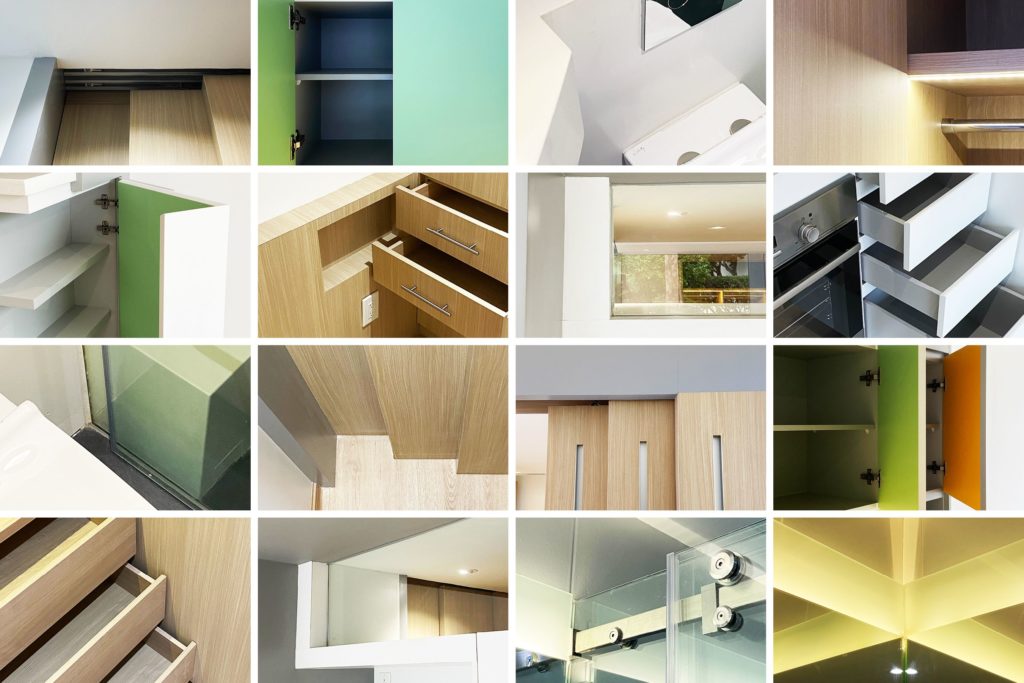

Interior innovations. A collage of premium features in a Cassette pod.

Cassette’s first-product is a compact 600 sq. ft. unit by the acclaimed modernist designers, Craig Hodgetts and Ming Fung. It offers a pleasant, light-filled space with a sensible demarcation of space and premium features like a laundry cabinet, double wardrobe, chef’s kitchen, and built-in storage. As Kaplan mentions, they doubtless represent an aesthetic and functional improvement over the standard fare found in America’s priciest cities. Pilot projects are already underway in L.A. with expected ground-breaking in 2023 or 2024.

A palette of possibility. Looking out from a Cassette pod.

We can’t wait to see it happen. To close with Cassette’s clever tag: “Ready. Set. Homes.”

Leave a Reply