Create the Perfect Skylight: Clear-PEP Panels by Design Composite

Using state-of-the-art technology in the Mittersill factory high up in Austrian Alps, honeycomb sheets of TRIcore are carefully bonded to a transparent thermoplastic top sheet to create Clear-PEP® panels. The company behind the innovative design is Design Composite, and behind the technical terms, the simplicity of scattered light through colored paneling is enough to sell its worth to residential or commercial projects.

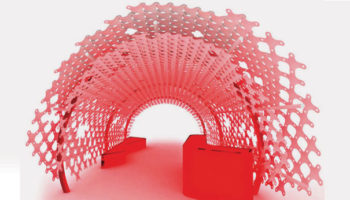

Clear-PEP Panels. Designed by Design Composite.

Colored Windows or Cladding: Natural Light Shines Through the Clear-PEP Panels by Design Composite

The series of Clear-PEP® is composed of five different types of panels that differ in the top sheet material and its structure, dimensions, and the color used. A material like this can be used on a skylight or exterior design of a building since it offers incredible thermal insulation. Design Composite also states on their website that “the innovative characteristic of the 19 mm dimensioned honeycomb hole structure not only gives the light structure panels a unique effect or depth, but also an extremely high structural rigidity.” This fact, along with the special edge closures, load-bearing external walls, point bracket-mounted facades, canopy roofs, or balcony paneling that are heavily tested by Design Composite themselves.

After the Clear-PEP panel bond the top sheet and TRIcore together, further processing of the cores is done on what they say is “one of the world’s biggest and most up-to-date flat bed lamination plants” where they use different coatings in PC and PMMA in a variety of colors. The end result can find purpose in both exterior and interior applications – used as a room divider, skylight, semi-transparency on windows, or outdoor canopies offering a touch of shade.

Leave a Reply