Live at IDS: “Your Countertops are Made of What?”

The short version of the technical specs on Paperstone - the Hoquiam, Washington-based manufacturer of flat panels for “architectural solid surface” - reads like a primer on some new-fangled/tech-wise material of the future, capable of withstanding exceptional compressive force: [with] “standard thicknesses available in 3/4 inch, 1 inch, and 1-1/4 inch panels, PaperStone can handle 45,000 pounds of compressive pressure per square inch and a 1-inch thick sheet will cantilever 4 feet with deflection of less than 1/16 inch.”

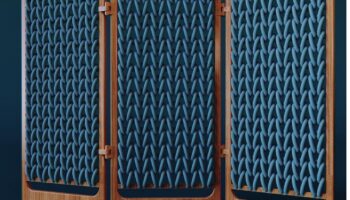

“Collaborations” exhibit at IDS. Constructed of PaperStone.

Hmmm, that’s quite a cantilever quotient, I find myself thinking… must be titanium, or one of the new breeds of thermoplastic polymers, or perhaps the upstart martensitic stainless steel. Au contraire, inner voice-this revolutionary green product is made of humble paper. Or, to be more precise, it’s an “organically-pigmented composite of petroleum-free phenolic resins, post-consumer waste, and recycled paper.”

That such a product is on the cutting edge of sustainable building practices may come as a mild shock-especially to anyone who’s experienced the ignominious revelation that his/her house was sheathed with masonite. Light years beyond the pressed cardboard of ages past, PaperStone achieves its strength, durability, work-ability, and beauty via the application of intense heat and pressure to create “a thoroughly impregnated network of cellulose fibers that give PaperStone its hardness, density, and strength in span or cantilevered designs.”

The manufacturers of this versatile product are serious about their commitment to sustainability, and to that end the input materials are 100% FSC Certified: this includes the recycled paper (procured from the paper mill nearby), the resin (extracted from the shells of cashews), and the water/UV-resistant finish (derived from the naturally-occuring protectant, carnauba wax).

In addition to all that makes it so wonderfully green, PaperStone can be worked just like wood (any finish carpenters out there can now breathe a communal sigh of relief): this means it can be routed, screwed, and chiseled without breaking into a thousand little shards; it can be sanded to finish quality; and when ripped lengthwise, its exposed edge will “resemble a solid surface product with a faint wood grain appearance.” The panels come pre-dyed in an alluring array of naturalistic tints derived from the color of the paper, pigments, and dyes used during manufacture, each of which is distinct and which continues to live and evolve after final application, much like a treasured leather jacket, “developing a seasoned appearance that is an inherent characteristic of the material… overall it will appear softer and deeper in tone.” So whether you choose Cabernet, Obsidian, Chocolate, or Plum; and whether you select PaperStone for your countertops, window sills, room partitions, paneling, or exterior cabinetry, the evolving luster of this timely product will be certain to match your own.

Leave a Reply